BEL Mark-1

Cost Effective

It is an extremely Low cost/economical and suitable for small batch production.

Features:

- Medium Power Transformer with Ac Voltage regulator for controlling the etching depth.

- Etching process is limited only for black marking.

- User friendly controller

Machine Includes:

- Electrolyte – 250ml

- Anti rust oil – 100ml

- Stencils 3-4 nos. (within 10sq.inch)

- Power chord – 1

- Red & Black cable – 1

- Marking head – 1

Enquire!

BEL Mark-2

A new unit designed for medium batch production or medium volume use.

Features:

- Medium power transformer with AC/DC voltage for black and white marking

- Special timer to control the cycle time and etching depth

Machine Includes:

- Electrolyte – 250ml

- Anti rust oil – 100ml

- Stencils 3-4 nos. (within 10sq.inch)

- Power chord – 1

- Red & Black cable – 1

- Marking head – 1

Enquire!

BEL Mark-3

Robust & rugged Model

This unit has been specially designed for heavy batch production or high volume use which requires automation.

Features:

- Mark-3 is equipped with memorable counter for batch count

- Timer for controlling cycle time

- Dose pump timer which takes care of the circulation of the electrolyte to avoid over heating an achieving longer stencil life

- AC/DC voltage for black/white marking

- Automatic assemble includes Pneumatic cylinder, dosing pump, foot pedal

Machine Includes:

- Electrolyte – 250ml

- Anti rust oil – 100ml

- Stencils 3-4 nos. (within 10sq.inch)

- Power chord – 1

- Red & Black cable – 1

- Marking head – 1

Enquire!

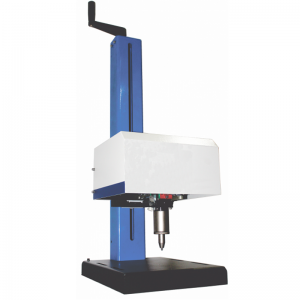

BLX – A1 – Bench Mounted

The BLX-A1 Bench mounted fibre laser marking system is

suitable for marking and engraving a wide

variety of metals, ceramics, and some plastics.

Widely used in industry for the marking or engraving

of QR codes, barcodes, logos, and serial numbers.

Can also be used for marking VIN and name plates.

Enquire!

BLX – A1 – Floor Standing

The BLX-A1 Floor standing fibre laser marking system is

suitable for marking and engraving a wide

variety of metals, ceramics, and some plastics.

Widely used in industry for the marking or engraving

of QR codes, barcodes, logos, and serial numbers.

Can also be used for marking VIN and name plates.

Enquire!

Heavy Marking Dot Peen

Type:

Pneumatic or Electric Heavy duty Dot peen.

Uses:

Used for very deep marking, serial numbering, dot matrix, logos

Size:

The 50mm x 30mm window size compact portable machines

80 X 30 and 150 X 50 models also available.

Advantages:

Convenient handles provided for effective marking

Can be mounted on the stand if required as an optional feature

Front fixture customised to suit application

Most compact construction fitted with linear

X and Y axes.

Disadvantages:

Not suitable for light marking needs

Enquire!

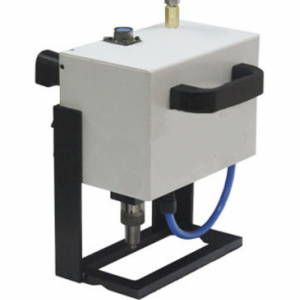

Integrated Dot Peen

Type:

Integrated marking head

Uses:

Angular, Circular, Mirror, Inverted, Serial Numbers, Date and Shift Codes

CSV File Marking is simple and straight forward.

Direct output to a barcode printer possible.

Mark Datamatrix & QRCode barcodes from the software.

Size:

The 50mm x 30mm window size compact portable machines

Advantages:

convenient fitment on existing machines.

4xM8 Mounting holes provided for firm mounting

Pneumatic and electronic versions

Can be used with all the controllers in both Pneumatic &

Electric versions.

Robust aluminium construction.

Most compact construction with maximum marking

window.

Enquire!

Laser Etched Business Cards

Laser Etched Business cards. Gloss black anodised aluminum. On checkout in the ‘additional information box’ State the information you want/contract details and an image link of your logo or you can email the information and image to sam@belmarking.com

Portable Marking Heads

Type:

Portable marking head

Uses:

Angular, Circular, Mirror, Inverted, Serial Numbers, Date and Shift Codes

CSV File Marking is simple and straight forward.

Direct output to a barcode printer possible.

Mark Datamatrix & QRCode barcodes from the software.

Size:

The 50mm x 30mm window size compact portable machines

Advantages:

The 50mm x 30mm window size compact portable machines

There is a pneumatic and electric version

Convenient handles provided for effective marking

Can be mounted on a stand if required as an optional feature

Front fixture customised to suit the application

Most compact construction fitted with linear

X and Y axes.

Disadvantages:

Hard wired, unable to mark far away from the controller

Enquire!

Semi-Automatic Marking System

Specially designed for marking on flat and round jobs e.g drills, taps, knives, clutches, shock-ups, engine valves, forceps, clamps, armatures, screw drivers.

The machine is useful for marking ID numbers and large logos

Features:

- Suitable for large volume production

- Dose pump controller for dosing the electrolyte

- Etching depth can be controller within 5-40 μm by varying parameters like voltage & timer

- Output per hour: 300-400 pcs

Machine Includes:

- Electrolyte – 250ml

- Anti rust oil – 100ml

- Stencils 3-4 nos. (within 10sq.inch)

- Power chord – 1

- Red & Black cable – 1

- Marking head – 1

Enquire!

Wifi Desktop Dot Peen

Type:

Bench Mounted Wifi Dot peen

Uses:

Angular, Circular, Mirror, Inverted, Serial Numbers, Date and Shift Codes

CSV File Marking is simple and straight forward.

Direct output to a barcode printer possible.

Mark Datamatrix & QRCode barcodes from the software.

Size:

120mm x 100mm area to cover 95% of Desktop marking applications.

80 X 30 and 150 X 50 models also available.

Advantages:

Hi-Performance Electo-Magnetic Stylus for 24 x 7 working.

Force of marking can be set using force codes.

Machine also available in Pneumatic version.

3Axis System with Rotary device or Motorised Z axis is also available.

Multilingual user interface available in 11 languages.

Operate over a Windows or Android based device.

Disadvantages:

Not portable may struggle to mark larger parts.

Enquire!

Wifi Hand held Dot Peen

Type:

Wifi operated Dot Peen

Uses:

Angular, Circular, Mirror, Inverted, Serial Numbers, Date and Shift Codes

CSV File Marking is simple and straight forward.

Direct output to a barcode printer possible.

Mark Datamatrix & QRCode barcodes from the software.

Size:

Marking Sizes: 50x30mm, 100x30mm, 150x30mm.

Advantages:

WIFI operated with Android and IOS control.

Long life battery.

User friendly.

No extra equipment such as keyboards and mice.

No cables.

Extremely portable.

Lightweight (2.5kg)

3 hours of continuous marking and 8 hours of normal marking.

Disadvantages:

Batteries require charging.

Must be within the range of the mobile device to make changes